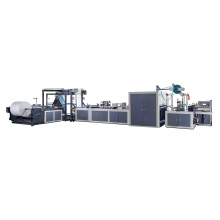

Máquinas de fabricación de bolsas de transporte

Información básica

Modelo: VB

Descripción del producto

Máquinas de fabricación de bolsas de TAIWAN

Carry bag Tipo de corte en caliente Salida máx. 360 pcs / min

Posible producto de las máquinas de fabricación de bolsas de transporte

Especificación de las máquinas de fabricación de bolsas de transporte

| Model Name | VB - Carry bags manufacturing machines |

| Final Product | T shirt bag |

| Application | T-shirt bag, Printed, Un-printed Shopping Bag |

| Material | HDPE, LDPE, Recycled Material, CaCO3 added |

| Output range | 30~360 pcs/min |

| Machine Width | 22-42 inches |

| Bag Width | 100mm~650mm |

| Bag Thickness | 0.008~0.1mm |

| Servo Motor | Yaskawa |

| Photocell | SICK |

| Delivery Time | 90~100 days |

| Warranty | 1 year |

| Technical Assistance | Engineers available to service machinery overseas |

Carry Bags Manufacturing Machines with Strong Bottom Welding | |

|

The carry bags manufacturing machines is suitable for producing HDPE/LDPE T-shirt bag with and without printing. This carry bags manufacturing machines is equipped with a photocell on each line, which helps to make sure of the printing area on the film. The carry bags manufacturing machines can cut the bags at same length. |

| |

|

The hot sealing/cutting knife makes the bottom welding of the bag stronger than other kind of bottom sealing carry bags manufacturing machines. Since the raw material cost keeps increasing, many film producers are producing films from recycled material or CaCO3 blended material, which is more difficult to be heated/sealed.

POLYSTAR specially designs the carry bags manufacturing machines with hot sealing/cutting knife for users who have films made from recycled material and CaCO3 blended material. The bottom of the bags can be well welded by this hot cutting system of carry bags manufacturing machines. |

|

| The Punching Mould Shape Can be Made Upon Customer's Request | |

| |

Clientes Historias de las bolsas

Blown film and carry bags manufacturing machines in Malawi | |

| The blown film machine is for producing maximum 800mm wide and 50 micron thick HDPE film. The carry bags manufacturing machines is equipped with hot cutting knife to reach the capacity of 300pcs per minute. By changing the knife mould, the carry bags manufacturing machines can produce T-shirt bag with different type of cut-off and size. |

|

| Carry bags manufacturing machines commissioned in Ethiopia | |

|

In April 2015, three sets of POLYSTAR carry bags manufacturing machines were commissioned in Ethiopia.

This producer started the plastic bag producing business in 2014. POLYSTAR helped the producer choose the machine needed for the production line, from blown film machine, printing machine to carry bags manufacturing machines.

The plastic bag producer is mainly producing T-shirt bags. POLYSTAR offered this producer 12 sets of compact type blown film machine to work with 3 sets of carry bags manufacturing machines. |

|

The carry bags manufacturing machines is able to process two rolls of film at once.

This hot cutting type carry bags manufacturing machines ensures the bottom sealing is strong enough. The carry bags manufacturing machines also includes two pieces of German made photocell to process printed films.

Capacity of the carry bags manufacturing machines is 360 pieces per minute. |

Por qué las máquinas de fabricación de bolsas POLYSTAR

Grupos de Producto : Máquina para hacer bolsas > Máquina para hacer bolsas de camisetas

Premium Related Products