Hopper de alimentación de reciclaje de la máquina

Información básica

Modelo: Repro-Direct

Descripción del producto

Material reciclado en la máquina de reciclaje de alimentación de tolva

| ||

| Granules | Hard plastic regrind | Fluff flakes |

Hopper de alimentación de reciclaje de la máquina

| |

|

Hopper feeding recycling machine is a universal recycling pelletizing machine suitable for pre-crushed, heavy rigid regrind scraps such as bottles, pipes, containers and lumps in the form of granules. Applicable materials are mainly HDPE, LDPE, PP, PA, PC, PU, PBU, ABS and others. |

| Hopper feeding recycling machine can also process light-weighted soft packaging material such as pre-crushed film flakes, PP raffia, PE/PP woven, PE foam and many others with the addition of a force feeder on the feeding hopper. |  |

|

In the Hopper feeding recycling machine, material is fed into the hopper directly without the need for pre-heating before extrusion. When processing rigid regrind or compressed washed flakes (processed by a squeezer dryer), this system ensures a faster and easier machine starting and stopping process comparing to other systems. |

Hopper de alimentación de reciclaje de la máquina en la planta del cliente

|

Polystar installed two sets of TR-150B waste plastic recycling machines in Dominican Republic. This waste plastic recycling machine are designed to work in line with a Italian washing line for contaminated HDPE and LDPE polyethylene film waste. A distinctive feature of this waste plastic recycling machine is its ability to process fluffy film flakes that are very light in weight. |

|

A Polystar 100kg per hour recycling line has been commissioned in Indonesia, for pelletizing PE and PP rigid waste. The Malang-based company is an outdoor furniture manufacturer with over 500 staff and 30 extruders. The waste is generated in-house from the manufacturing of outdoor furniture.With the addition of this new pelletizing/recycling line, the company can now turn these waste back into good quality, reusable pellets (granules), and then put it directly back into the extrusion process, for making the products (furniture) again. |

¿Por qué POLYSTAR Hopper de alimentación de reciclaje de la máquina

|

High quality recycled pellets

Up to 100% reusability back into your production line. Post-industrial waste generated from production of film, raffia and injection regrind can be recycled efficiently by Hopper feeding recycling machine and put right back into your production lines. Meaning less amount of new (raw) material needs to be used in your production.

|

|

Manufacturing with Precision

CE certified Hopper feeding recycling machine

with total quality control

Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency Strong research and design team |

|

Service and Communication Overseas Hopper feeding recycling machine installation service and training are available |

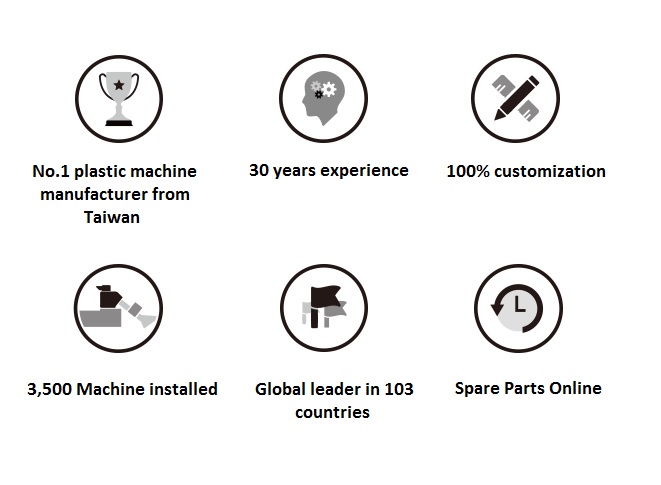

Our Experience, Your Advantage

| |

POLYSTAR Página web:

Grupos de Producto : Máquina de reciclaje de plástico > Máquina de reciclaje de alimentación de la tolva

Premium Related Products